We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Welding Tables Direct

Specialists in the field of welding and cutting.

One of the UK's largest distributors of Strong Hand Tools and BuildPro Welding Tables.

Tailored Welding Workshop Solutions.

Specialist Turnkey Services from Weld Safe Products Limited.

Providing you with the ideal solution to meet your needs and suit your budget.

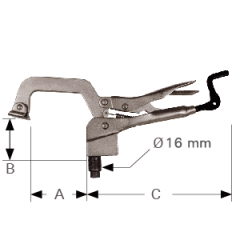

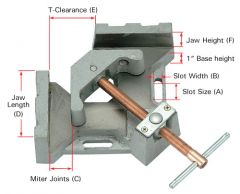

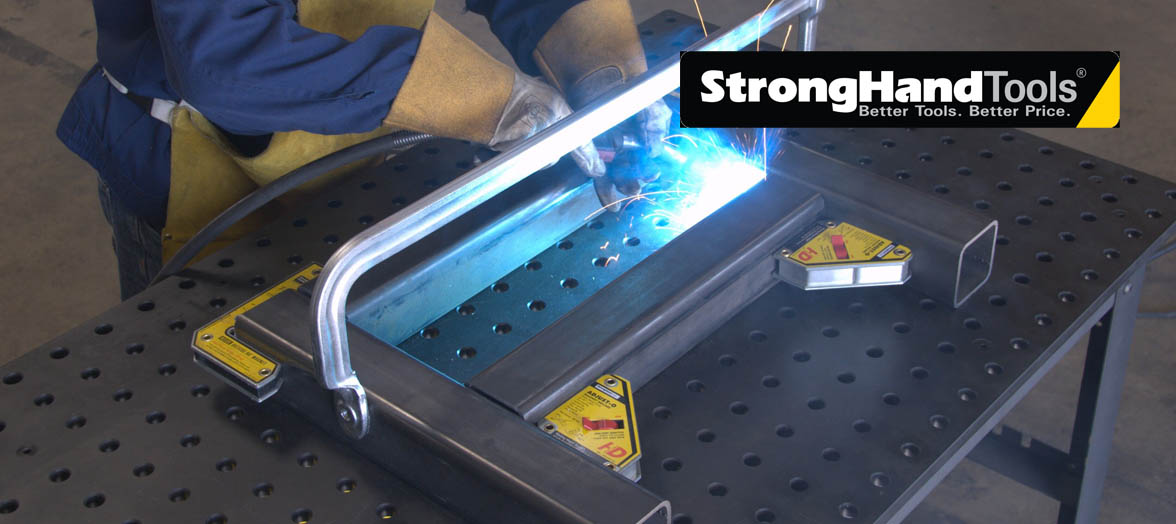

Innovative Fit-Up Tools.

Clamps, Magnets, Pliers and Welding Tables from StrongHand Tools.

Dedicated to designing innovative, time-saving workholding tools.

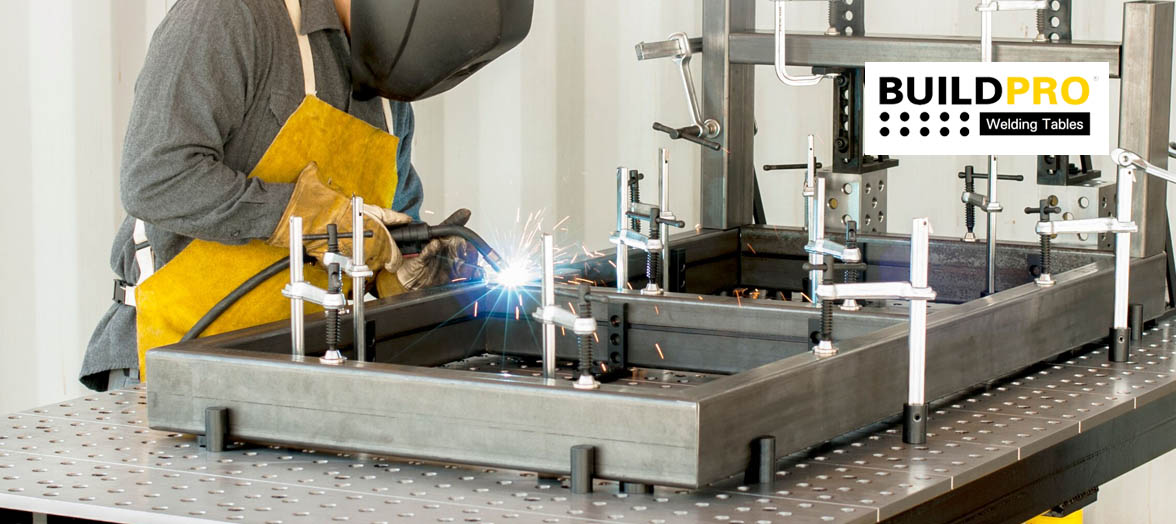

Fixture Efficiently and Fabricate Accurately.

Affordable Modular Welding Tables from BuildPro.

Increase productivity and work quality while reducing project lead time.

Free delivery for orders over £75 (excl. VAT).

Place your order before 12pm for same day dispatch.

Exclusions apply.

Specialists in the field of welding and cutting.

Free UK delivery on all orders over £75.00 + VAT.

Quality products at competitive prices.

Advice available from our welding experts.

Professional Service

As specialists in the field of welding and cutting, we pride ourselves in being able to provide our customers with the best quality products available from a selection of leading industry brands.

Videos

Featured Products

Discover our most popular products.

-

BuildPro® MAX Welding Table - 1200 x 1200 mm with Adjustable Legs & Mobility Castors£3,073.97 £2,561.64Out of stock

BuildPro® MAX Welding Table - 1200 x 1200 mm with Adjustable Legs & Mobility Castors£3,073.97 £2,561.64Out of stock -